Inside the Studio: How Master Hatmaker Michael Patrick Hoyle Crafts Seattle’s Finest Handmade Hats

Welcome to Hoyle Hat Co., Seattle’s premier destination for handcrafted, heirloom-quality headwear. Behind every brim and band is the hand of Michael Patrick Hoyle, a master hatmaker whose studio in downtown Seattle blends tradition with creative precision.

Whether you're shopping for a one-of-a-kind hat or exploring the craft yourself, here’s an insider’s look at how it all comes together—right here at HoyleHat.com.

Meet the Maker: Michael Patrick Hoyle

Founder of Hoyle Hat Co., Michael Patrick Hoyle is more than a craftsman—he’s a preservationist of old-world millinery. Right downtown near the waterfront & next to Seattle’s iconic Pike Place Market corridor meets Belltown proper, Michael shapes hats that carry legacy, intention, and Northwest soul.

The Essential Tools of the Trade

Before you shape your first crown or curve your first brim, you’ll need the right tools. The process is tactile, meditative, and steeped in heritage—and that means honoring the craft with the correct gear:

-

Hat Blocks: These wooden molds help form the crown and brim of your hat. You’ll need different shapes depending on your style (teardrop, fedora, gambler, etc.).

-

Flange Boards: Used to shape the brim after blocking, giving it a sharp, uniform finish.

-

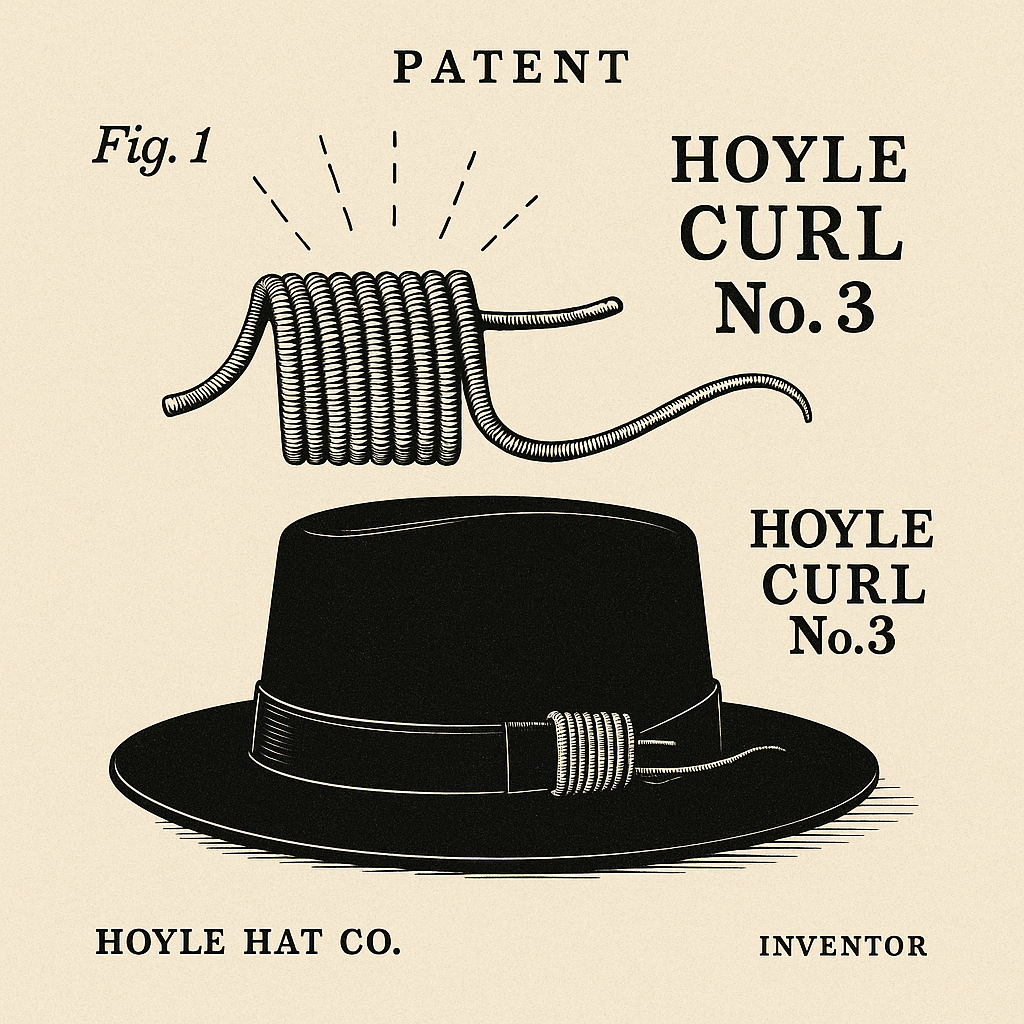

Hat Iron / Brim Curling Shackles: These heated tools help flatten or curl the brims—vital for getting that perfect edge.

-

Pouncing Pads & Brushes: For finishing the felt or wool with finesse, smoothing surfaces, and giving it that luxurious feel.

-

String Stretchers & Conformateurs: Used for resizing and fitting hats to your exact head shape.

-

Sewing Machine (Industrial or Wilcox & Gibbs Chainstitch): For stitching sweatbands or decorative ribbon finishes.

Step-by-Step: Making a Handmade Hat

1. Choose Your Material

Most handmade hats start with either fur felt, wool felt, or straw. For beginners, wool is forgiving and easier to shape.

2. Steam & Shape the Crown

Using a steamer or boiling kettle, saturate the felt with steam until it becomes soft and malleable. Place it over your hat block and pull it down tightly, pinning the base to hold shape. Let it dry for 12-24 hours.

3. Brim Blocking

Once the crown has set, it’s time to shape the brim. Steam it again and lay it over a flange board or use a brim shackle to get your desired style. For upturned edges, a curling iron is your best friend.

4. Cutting & Pouncing

Trim the brim evenly, using a ruler or pre-set gauge. Then sand the surface lightly with a pouncing pad or finishing brush to clean the texture.

5. Add the Sweatband

A leather or cotton sweatband gets sewn to the inside base of the crown. It’s what gives your hat comfort, structure, and longevity. This is often done with an industrial chainstitch machine or by hand.

6. Dress It Up

This is where your brand comes alive. Choose ribbon, stitching, feathers, branded pins, or even burned initials. Let your story show.

Where to Start if You're New

If you're just beginning your hat-making journey, start with a basic wool felt body, a steamer, and a crown block in your preferred shape. From there, expand your toolkit as your skills grow. Consider sourcing your materials from trusted suppliers like Pajamas Felt, Puschel, or Hat Shapers.

And yes, if you’re ready to take it to the next level—Shopify is the perfect platform to tell your story and sell your pieces. With beautiful templates, product management, and blog integration, you can build your hat-making empire right from your studio bench.

Final Thoughts: Crafting with Intention

There’s something sacred about creating with your hands—especially when your work becomes a part of someone’s life. Every crease, every brushstroke, every band tells a story. Whether you’re creating one for yourself or hundreds for a collection, handmade hats are wearable legacy pieces.

So roll up your sleeves, fire up the steamer, and start crafting your own chapter in millinery history.

We make. We source. You enjoy.